1 Ulwakhiwo lwangaphakathi lweprinta yelaser

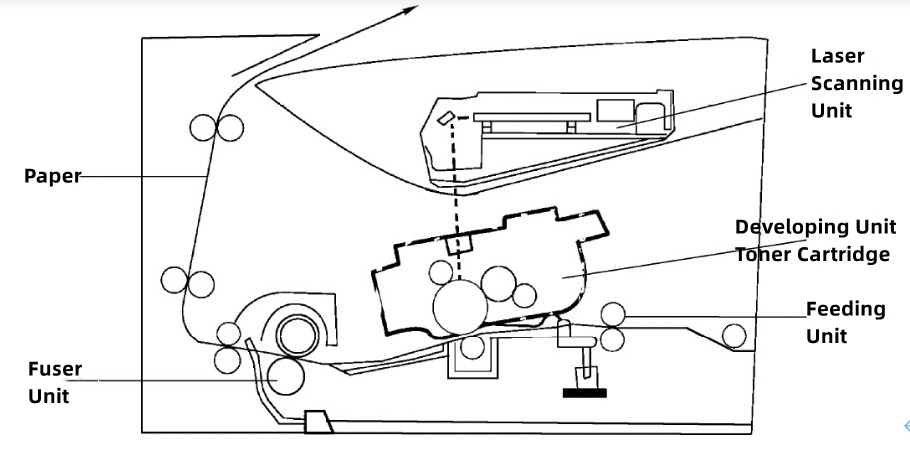

Ulwakhiwo lwangaphakathi lweprinta yelaser luneendawo ezine eziphambili, njengoko kubonisiwe kuMfanekiso 2-13.

Umfanekiso 2-13 Ulwakhiwo lwangaphakathi lweprinta yelaser

(1) Iyunithi yeLaser: ikhupha umqadi welaser onolwazi olubhaliweyo ukuze iveze igubu elinomoya oshushu.

(2) Iyunithi Yokondla Iphepha: lawula iphepha ukuba lingene kwiprinta ngexesha elifanelekileyo kwaye liphume kwiprinta.

(3) Iyunithi yoPhuhliso: Gquma inxalenye eveziweyo yedrama ethambileyo ngetoner ukuze wenze umfanekiso onokubonwa ngamehlo enyama, uze uwudlulisele kumphezulu wephepha.

(4) Iyunithi Yokulungisa: I-toner egquma umphezulu wephepha iyanyibilika kwaye iqiniswe ngokuqinileyo ephepheni kusetyenziswa uxinzelelo kunye nobushushu.

2 Umgaqo wokusebenza weprinta yelaser

Iprinta yelaser sisixhobo esikhupha imveliso esidibanisa iteknoloji yokuskena yelaser kunye neteknoloji yokufota nge-elektroniki. Iiprinta zelaser zinemisebenzi eyahlukeneyo ngenxa yeemodeli ezahlukeneyo, kodwa ulandelelwano lokusebenza kunye nomgaqo ziyafana.

Xa sithatha iiprinta ze-HP laser eziqhelekileyo njengomzekelo, ulandelelwano lokusebenza lumi ngolu hlobo lulandelayo.

(1) Xa umsebenzisi ethumela umyalelo wokuprinta kwiprinta ngenkqubo yokusebenza yekhompyutha, ulwazi lwemizobo oluza kuprintwa luqala luguqulwe lube lulwazi lwesibini nge-driver yeprinta, kwaye ekugqibeleni luthunyelwe kwibhodi yokulawula ephambili.

(2) Ibhodi yokulawula ephambili ifumana kwaye itolike ulwazi oluvela kwi-binary oluthunyelwe ngumqhubi, ilulungelelanise nomqadi welaser, kwaye ilawula inxalenye yelaser ukuba ikhuphe ukukhanya ngokweenkcukacha. Kwangaxeshanye, umphezulu wedrum ethambileyo utshajwa sisixhobo sokutshaja. Emva koko umqadi welaser onolwazi olunemifanekiso uveliswa yinxalenye yokuskena yelaser ukuze iveze idrum ethambileyo. Umfanekiso ofihlakeleyo we-electrostatic wenziwa phezu komphezulu wedrum yetoner emva kokuvezwa.

(3) Emva kokuba ikhatriji yetoner idibene nenkqubo ephuhlisayo, umfanekiso ofihlakeleyo uba yimizobo ebonakalayo. Xa idlula kwinkqubo yokudlulisa, itoner idluliselwa ephepheni phantsi kwesenzo sombane wesixhobo sokudlulisa.

(4) Emva kokuba udluliselo lugqityiwe, iphepha linxibelelana ne-sawtooth echitha umbane, lize likhuphe itshaja ephepheni liye emhlabeni. Ekugqibeleni, lingena kwinkqubo yokulungisa ubushushu obuphezulu, kwaye imizobo kunye nombhalo owenziwe yi-toner zifakwe ephepheni.

(5) Emva kokuba ulwazi olunemifanekiso luprintiwe, isixhobo sokucoca siyasusa i-toner engadluliselwanga, size singene kumjikelo olandelayo wokusebenza.

Zonke iinkqubo zokusebenza ezingentla kufuneka zidlule kumanyathelo asixhenxe: ukutshaja, ukuvezwa, uphuhliso, ukudluliselwa, ukususwa kombane, ukulungiswa, kunye nokucoca.

1>. Intlawulo

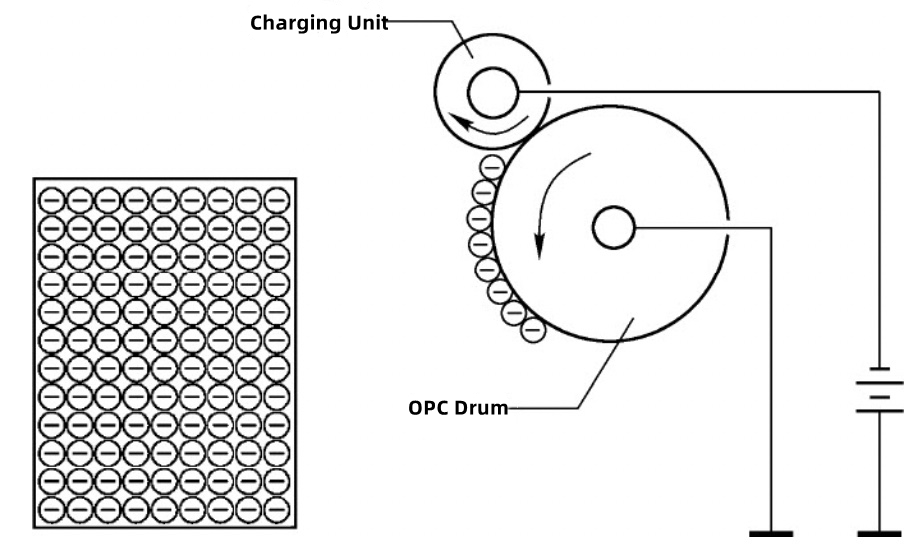

Ukuze idrama ethambileyo neyinyamekileyo ikwazi ukufunxa ithoni ngokweenkcukacha zemizobo, idrama ethambileyo neyinyamekileyo kufuneka itshajwe kuqala.

Okwangoku kukho iindlela ezimbini zokutshaja iiprinta ezithengiswayo, enye kukutshaja i-corona kwaye enye kukutshaja i-roller, zombini ezineempawu zazo.

Ukutshaja kweCorona yindlela yokutshaja engathanga ngqo esebenzisa i-substrate eqhubayo yedrama ethambileyo njenge-electrode, kwaye ucingo lwesinyithi oluncinci kakhulu lubekwa kufutshane nedrama ethambileyo njengenye i-electrode. Xa kukopishwa okanye kuprintwa, kufakwa i-voltage ephezulu kakhulu kwintambo, kwaye indawo ejikeleze ucingo yenza intsimi yombane enamandla. Phantsi kwesenzo sentsimi yombane, ii-ion ezine-polarity efanayo nentambo ye-corona zigeleza kumphezulu wedrama ethambileyo. Ekubeni i-photoreceptor kumphezulu wedrama ethambileyo inokumelana okuphezulu ebumnyameni, itshaja ayizukugeleza, ngoko ke amandla omphezulu wedrama ethambileyo aya kuqhubeka enyuka. Xa amandla enyuka aye kwi-power ephezulu yokwamkelwa, inkqubo yokutshaja iyaphela. Ingxaki yale ndlela yokutshaja kukuba kulula ukuvelisa imitha kunye ne-ozone.

Ukutshaja i-charging roller yindlela yokutshaja ngokunxibelelana, engadingi i-voltage ephezulu yokutshaja kwaye inobuhlobo nokusingqongileyo. Ke ngoko, uninzi lweeprinta ze-laser zisebenzisa ii-charging roller ukutshaja.

Masithathe ukutshaja kwerola yokutshaja njengomzekelo ukuze siqonde yonke inkqubo yokusebenza kweprinta yelaser.

Okokuqala, inxalenye yesekethe ye-high-voltage ivelisa i-voltage ephezulu, etshaja umphezulu we-photosensitive drum ngombane ongeyonyani nge-charging component. Emva kokuba i-photosensitive drum kunye ne-charging roller zijikeleza ngokulinganayo umjikelo omnye, umphezulu wonke we-photosensitive drum utshaja nge-charging engeyonyani efanayo, njengoko kubonisiwe kuMfanekiso 2-14.

Umfanekiso 2-14 Umzobo wesicwangciso sokutshaja

2>. ukuvezwa

Ukuvezwa kwenziwa kujikeleze idrama ethambileyo, evezwa nge-laser beam. Umphezulu wedrama ethambileyo yimaleko ethambileyo, umaleko othambileyo ugubungela umphezulu we-aluminium alloy conductor, kwaye i-aluminium alloy conductor iphantsi komhlaba.

Umaleko oveliswa yifoto yinto eveliswa yifoto, ebonakaliswa ngokuba yi-conductive xa ivezwa ekukhanyeni, kwaye ifake i-insulation ngaphambi kokuba ivezwe. Ngaphambi kokuba ivezwe, i-uniform charge ihlawuliswa sisixhobo sokutshaja, kwaye indawo evezwa yifoto emva kokuba ivezwe yi-laser iya kuba yi-conductor ngokukhawuleza kwaye ijikeleziswe ne-aluminium alloy conductor, ngoko ke i-charge ikhululwa emhlabeni ukuze yenze indawo yombhalo ephepheni lokuprinta. Indawo engavezwanga yi-laser isagcina i-charge yokuqala, yenza indawo engenanto ephepheni lokuprinta. Ekubeni lo mfanekiso womlinganiswa ungabonakali, ubizwa ngokuba ngumfanekiso ofihlakeleyo we-electrostatic.

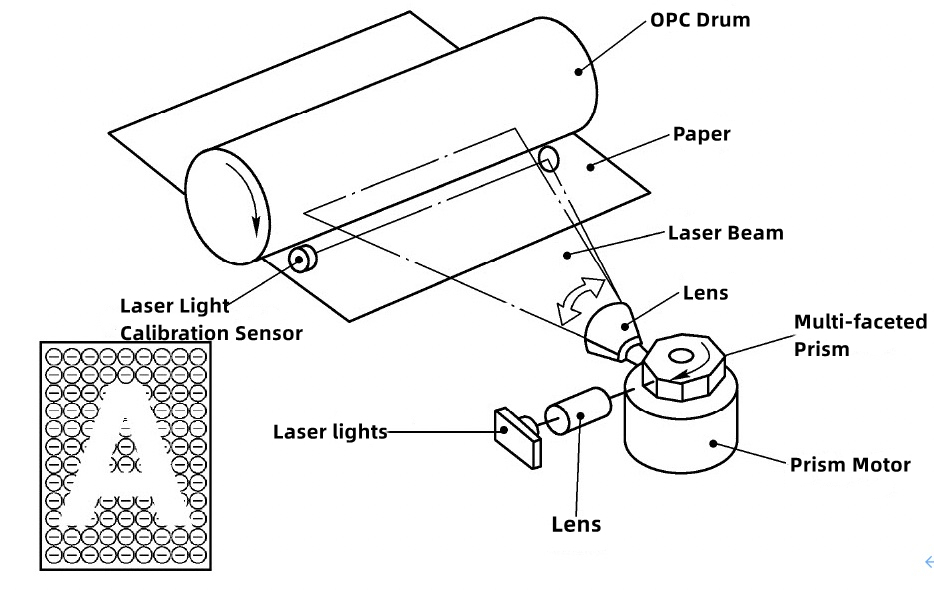

Isixhobo sokuvavanya esihambelanayo sikwafakelwe kwisixhobo sokuvavanya. Umsebenzi waso kukuqinisekisa ukuba umgama wokuskena uhambelana ukuze umqadi welaser okhanyiswe kumphezulu wedrum ethambileyo ukuze ufumane isiphumo esihle kakhulu sokujonga.

Isibane selaser sikhupha umqadi welaser onolwazi ngoonobumba, olukhanyisa kwiprism ejikelezayo enemiba emininzi, kwaye iprism ebonakalisa umqadi welaser kumphezulu wedrama ebonakalisa ukukhanya ngeqela leelensi, ngaloo ndlela iskena idrama ebonakalisa ukukhanya ngokuthe tye. Injini ephambili iqhuba idrama ebonakalisa ukukhanya ukuba ijikeleze rhoqo ukuze ikwazi ukuskena ngokuthe nkqo kwedrama ebonakalisa ukukhanya yilaser ekhupha ukukhanya. Umgaqo wokuvezwa uboniswe kuMfanekiso 2-15.

Umfanekiso 2-15 Umzobo wesicwangciso sokuvezwa

3>. uphuhliso

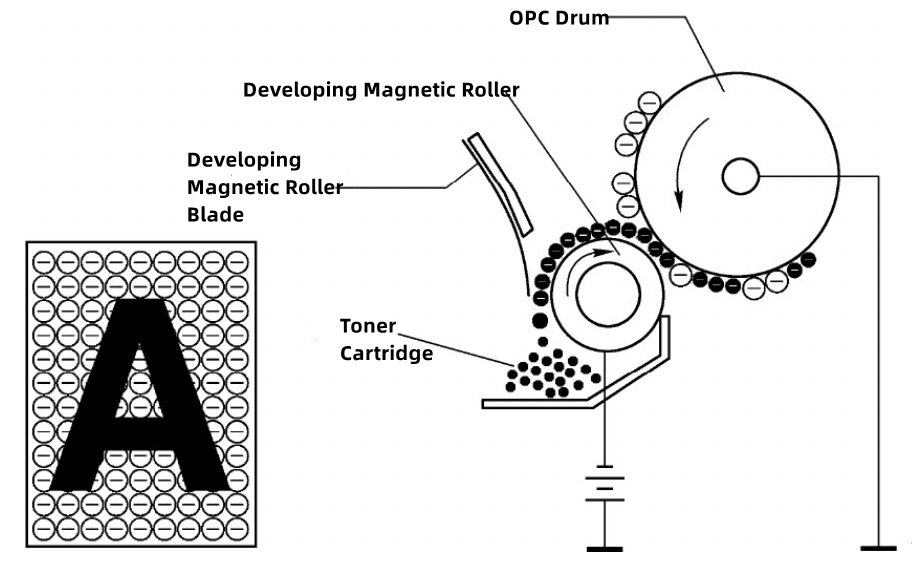

Uphuhliso yinkqubo yokusebenzisa umgaqo wokugxothwa kwabantu besini esinye kunye nokutsalwa kweetshaja zombane zesini esahlukileyo ukuguqula umfanekiso ofihlakeleyo we-electrostatic ungabonakali emehlweni abe yimizobo ebonakalayo. Kukho isixhobo semagnethi embindini we-magnetic roller (ekwabizwa ngokuba yi-developing magnetic roller, okanye i-magnetic roller ngamafutshane), kwaye i-toner ekwi-powder bin iqulethe izinto zemagnethi ezinokufunxwa yi-magnethi, ngoko ke i-toner kufuneka itsalwe yi-magnethi embindini we-magnetic roller esakhulayo.

Xa idrama ethambileyo ijikeleza kwindawo apho idibana khona nerola yemagnethi ekhulayo, inxalenye yomphezulu wedrama ethambileyo engakhanyiswa yilaser ine-polarity efanayo ne-toner, kwaye ayizukufunxa i-toner; ngelixa inxalenye ekhanyiswa yilaser ine-polarity efanayo ne-toner. Ngokuchaseneyo, ngokwemigaqo yokugxotha abantu besini esinye kunye nokutsala abantu besini esahlukileyo, i-toner ifunxwa kumphezulu wedrama ethambileyo apho i-laser ikhanyiswa khona, kwaye emva koko imifanekiso ye-toner ebonakalayo yenziwa phezu komphezulu, njengoko kubonisiwe kuMfanekiso 2-16.

Umfanekiso 2-16 Umzobo womgaqo wophuhliso

4>. ushicilelo lokudlulisa

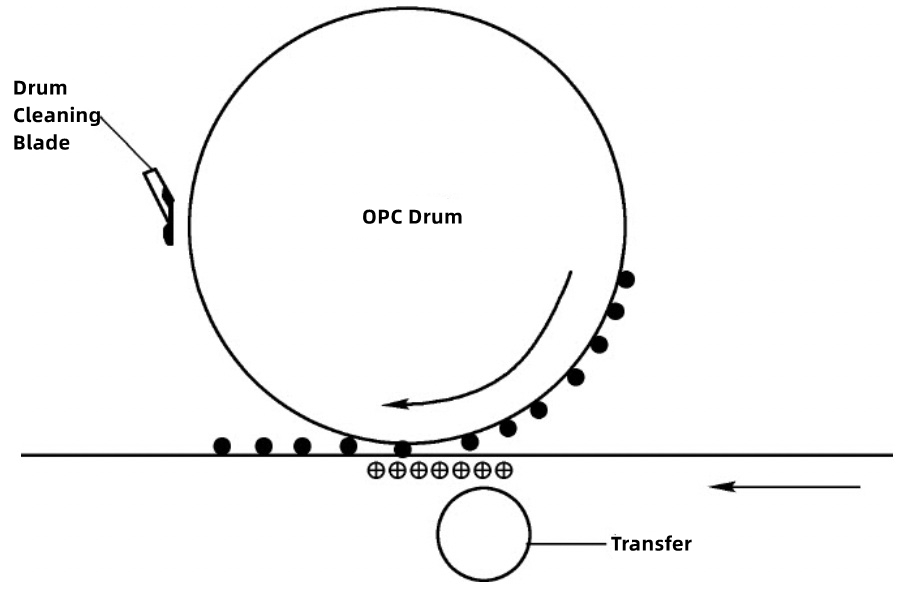

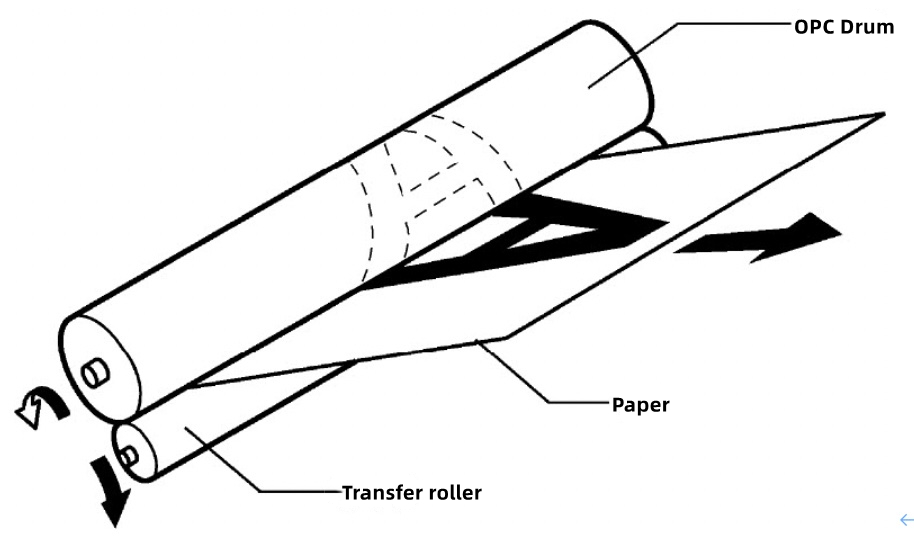

Xa i-toner idluliselwa kufutshane nephepha lokuprinta nge-drum ethambileyo, kukho isixhobo sokudlulisa ngasemva kwephepha ukuze kufakwe ukudluliselwa koxinzelelo oluphezulu ngasemva kwephepha. Ngenxa yokuba i-voltage yesixhobo sokudlulisa iphezulu kune-voltage yendawo yokuvezwa kwe-drum ethambileyo, imizobo, kunye nombhalo owenziwe yi-toner zidluliselwa kwiphepha lokuprinta phantsi kwesenzo sombane wesixhobo sokutshaja, njengoko kubonisiwe kuMfanekiso 2-17. Imizobo kunye nombhalo uvela kumphezulu wephepha lokuprinta, njengoko kubonisiwe kuMfanekiso 2-18.

Umfanekiso 2-17 Umzobo wesicwangciso sokuprinta okudluliselweyo (1)

Umfanekiso 2-18 Umzobo wesicwangciso sokuprinta okugqithisileyo (2)

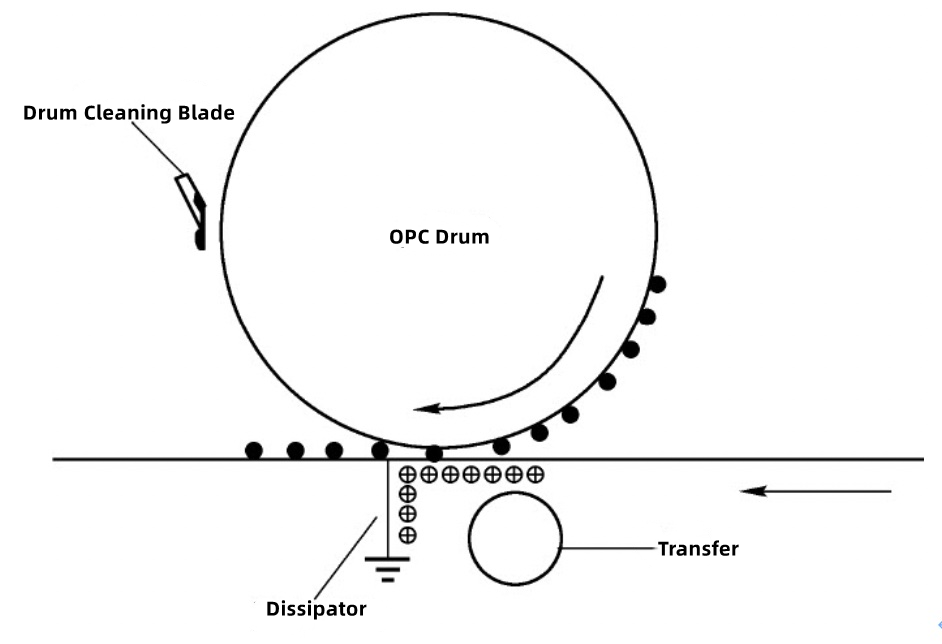

5>. Umbane ongcolileyo

Xa umfanekiso wetoner udluliselwa kwiphepha lokuprinta, itoner igubungela kuphela umphezulu wephepha, kwaye isakhiwo somfanekiso esenziwe yitoner sitshatyalaliswa lula ngexesha lenkqubo yokuhambisa iphepha lokuprinta. Ukuqinisekisa ukuthembeka komfanekiso wetoner ngaphambi kokulungisa, emva kokudlulisela, iya kudlula kwisixhobo sokususa esingashukumiyo. Umsebenzi wayo kukususa i-polarity, ukuphelisa zonke iindleko kunye nokwenza iphepha lingathathi cala ukuze iphepha lingene kwiyunithi yokulungisa kakuhle kwaye liqinisekise ukuprintwa kwemveliso. Umgangatho wemveliso, uboniswe kuMfanekiso 2-19.

Umfanekiso 2-19 Umzobo wesicwangciso sokususwa kwamandla

6>. ukulungiswa

Ukufudumeza nokulungisa yinkqubo yokufaka uxinzelelo kunye nokufudumeza kumfanekiso wetoner ofakwe ephepheni lokuprinta ukuze kunyibilikiswe itoner kwaye kufakwe ephepheni lokuprinta ukuze kwenziwe umfanekiso oqinileyo kumphezulu wephepha.

Eyona nto iphambili kwi-toner yi-resin, iqondo lokunyibilika kwe-toner limalunga ne-100°C, kwaye ubushushu berola yokufudumeza yeyunithi yokulungisa bumalunga ne-180°C.

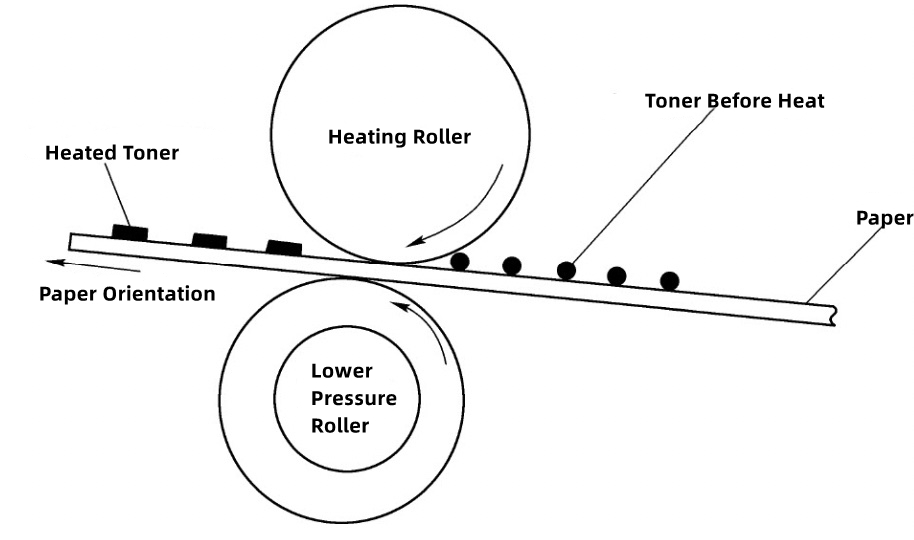

Ngexesha lenkqubo yokuprinta, xa ubushushu be-fuser bufikelela kubushushu obumiselweyo obumalunga ne-180°C xa iphepha elifunxa i-toner lidlula kwisithuba esiphakathi kwe-heating roller (ekwaziwa ngokuba yi-upper roller) kunye ne-pressure rubber roller (ekwaziwa ngokuba yi-pressure lower roller, i-lower roller), inkqubo yokudibanisa iya kugqitywa. Ubushushu obuphezulu obuvelisiweyo bufudumeza i-toner, enyibilikisa i-toner ephepheni, ngaloo ndlela yenza umfanekiso oqinileyo kunye nombhalo, njengoko kubonisiwe kuMfanekiso 2-20.

Umfanekiso 2-20 Umzobo oyintloko wokulungiswa

Ngenxa yokuba umphezulu we-heating roller ugqunywe nge-coating engelula ukuyinamathela kwi-toner, i-toner ayizukunamathela kumphezulu we-heating roller ngenxa yobushushu obuphezulu. Emva kokulungiswa, iphepha lokuprinta lahlulwa kwi-heating roller nge-separation claw kwaye lithunyelwe ngaphandle kweprinta nge-paper feed roller.

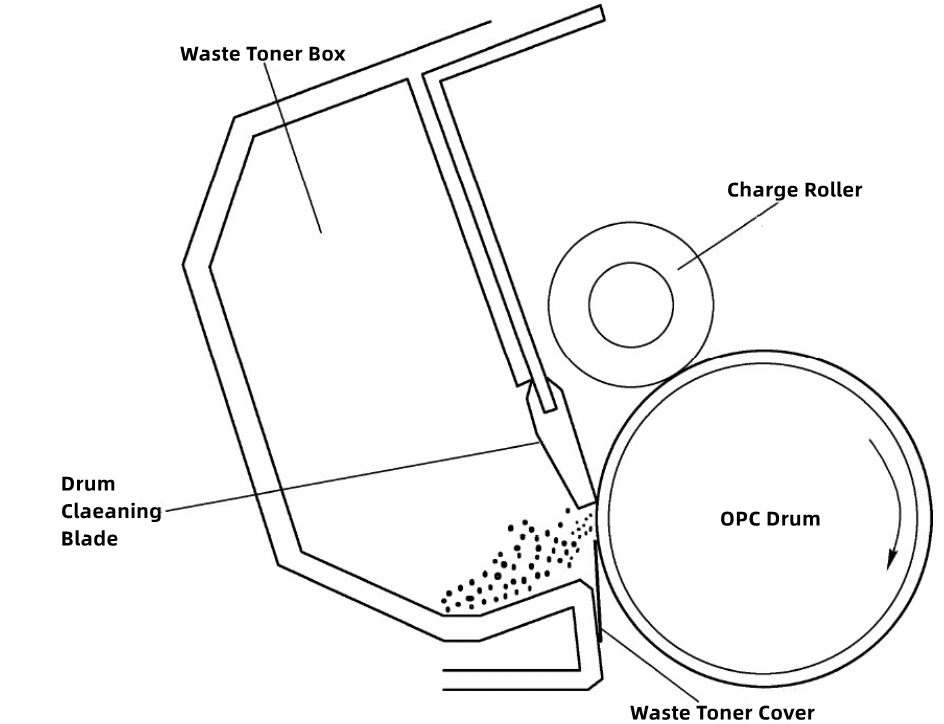

Inkqubo yokucoca kukukrwela i-toner kwidramu ethambileyo nengenakususwa ukusuka kumphezulu wephepha ukuya kwibhini ye-toner yenkunkuma.

Ngexesha lenkqubo yokudlulisa, umfanekiso we-toner kwidrama ethambileyo ayinakudluliselwa ngokupheleleyo ephepheni. Ukuba ayicocwanga, i-toner eseleyo kumphezulu wedrama ethambileyo iya kuthwalelwa kumjikelo olandelayo wokuprinta, itshabalalise umfanekiso osandul’ ukwenziwa, ngaloo ndlela ichaphazela umgangatho wokuprinta.

Inkqubo yokucoca yenziwa ngesixhobo sokukrwela irabha, esimsebenzi waso kukucoca idrama enokuthambeka kwefoto ngaphambi komjikelo olandelayo wokuprinta idrama enokuthambeka kwefoto. Ngenxa yokuba iblade yesixhobo sokukrwela irabha ayigugi kwaye iguquguquka, iblade yenza i-engile esikiweyo kunye nomphezulu wedrama enokuthambeka kwefoto. Xa idrama enokuthambeka kwefoto ijikeleza, i-toner ephezu komphezulu ikrwelwa kwibhini ye-toner yenkunkuma yisixhobo sokukrwela, njengoko kubonisiwe kuMfanekiso 2-21 obonisiweyo.

Umfanekiso 2-21 Umzobo wesicwangciso sokucoca

Ixesha lokuthumela: Februwari-20-2023